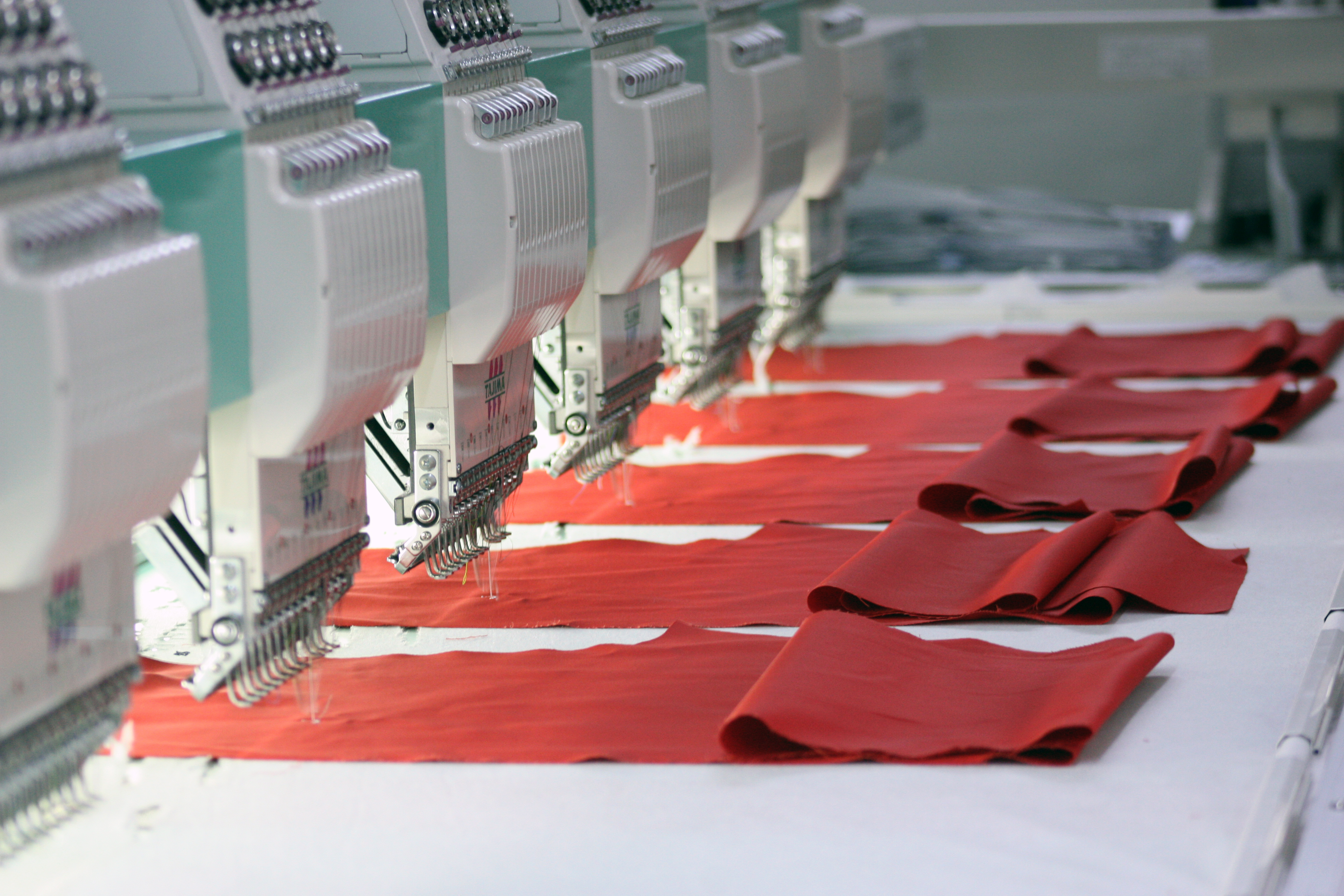

SEWING SHOP

Our company, which specializes in men's and women's ready-made clothing, is an integrated facility that

can meet all kinds of demands with its state-of-the-art machinery, cutting / sewing / pressing

departments and experienced staff. All production processes are regularly monitored thanks to ERP

software and production movements are kept under control. All operators work in accordance with the

announced operation methods, machine use and maintenance instructions. Sewing and pressing operations

are controlled by in-line controllers in terms of mechanics, method and ergonomics, and the quality of

production is maintained at the desired criteria.Jacket production track; It consists of five sections:

Body, Lining, Sleeve, Assembly and Ironing Press section, and has a daily production capacity of 1100

jackets. Trouser production track; It consists of three sections: Preparation, Assembly, Ironing Press

section, and has a daily production capacity of 1100 trousers. Vest production track; It consists of

three sections: Preparation, Assembly and Ironing Press band and has a daily capacity of 250 vests. Many

operations in the production lines are carried out with the latest technology automation systems

(automatic machines such as flap, pocket cover, pleat/dart, Sason, side folding, lining, overcasting,

buttonhole, button, etc., as well as carousel system PLS computer- controlled intermediate and final

presses, etc.). Product quality and efficiency have been increased to the highest level. With rail

transfer systems designed to move semi-finished and finished products on the production line,

transportation is eliminated and stock control, which is the basis of the lean production philosophy, is

achieved.