What we do

GİTEKS KONFEKSİYON SAN. ve TİC. A.Ş., the leading company in the apparel industry, has become Turkey's most rapidly developing, innovative, high productivity and quality men's ready-to-wear production center and has become the main manufacturer of many brands of the world, including Orka Holding's global brands Damat, Tween, D'S Damat, TWN in the domestic market.

Our Values

Our Social Responsibility Policies

As part of the value it attaches to people, Giteks A.Ş. act with a sense of social responsibility in its activities as one of the fundamental and unchangeable elements of the management approach accepts. To our stakeholders through sustainable growth, fulfill our responsibilities towards the environment and society is our business purpose.

Our Responsibilities Towards Nature and the Environment

Not only our own lives but also the lives of the people around us we work to improve the quality of our work, and by increasing this endeavor We keep it going. We take part in social projects of our own choice. we'll get it. Time, energy and financial resources for social projects we are volunteers.

Our Human Resources Policy

With the awareness that human resources are the source of success, every GİTEKS A.Ş. contributes to the personal and professional development of employees human resources that will create a sustainable learning environment resources policies are implemented.

INFORMATION TECHNOLOGIES AND DIGITALIZATION

Based on the belief that development is the

basis of sustainable success, GITEKS Inc. uses technology effectively in order to achieve the highest

efficiency in production processes and organizes training and seminars in this direction for its

employees.

Based on the belief that development is the

basis of sustainable success, GITEKS Inc. uses technology effectively in order to achieve the highest

efficiency in production processes and organizes training and seminars in this direction for its

employees.

Fabric and auxiliary materials are subjected to

all kinds of physical tests (fastness tests, strength tests, fabric lot and wing tests, washing and steam

absorption tests, etc.) and their usability is analyzed within internationally accepted tolerances.

Fabric and auxiliary materials are subjected to

all kinds of physical tests (fastness tests, strength tests, fabric lot and wing tests, washing and steam

absorption tests, etc.) and their usability is analyzed within internationally accepted tolerances.

PHYSICAL TESTING LABORATORY

RAW MATERIAL AND WAREHOUSE

After the order is entered into the system, the

purchasing department checks the current stock status via the ERP system and creates a purchase order for

the required raw material. The unit quantity of the ordered raw material and its suitability to the

required specifications are determined through input controls. Raw materials accepted according to

delivery and receipt standards are stacked in the areas determined in the addressing system and recorded

in the ERP system.

After the order is entered into the system, the

purchasing department checks the current stock status via the ERP system and creates a purchase order for

the required raw material. The unit quantity of the ordered raw material and its suitability to the

required specifications are determined through input controls. Raw materials accepted according to

delivery and receipt standards are stacked in the areas determined in the addressing system and recorded

in the ERP system.

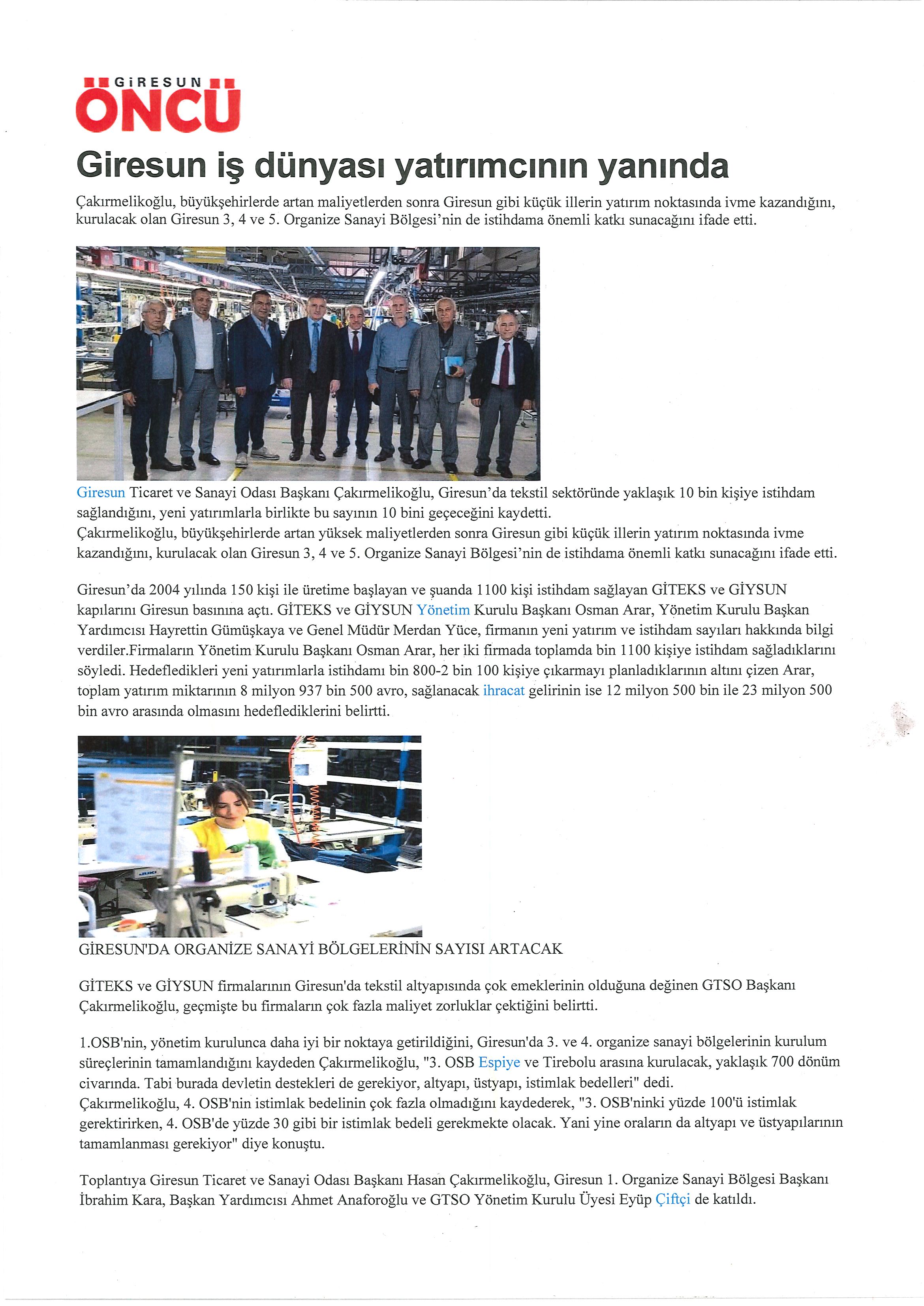

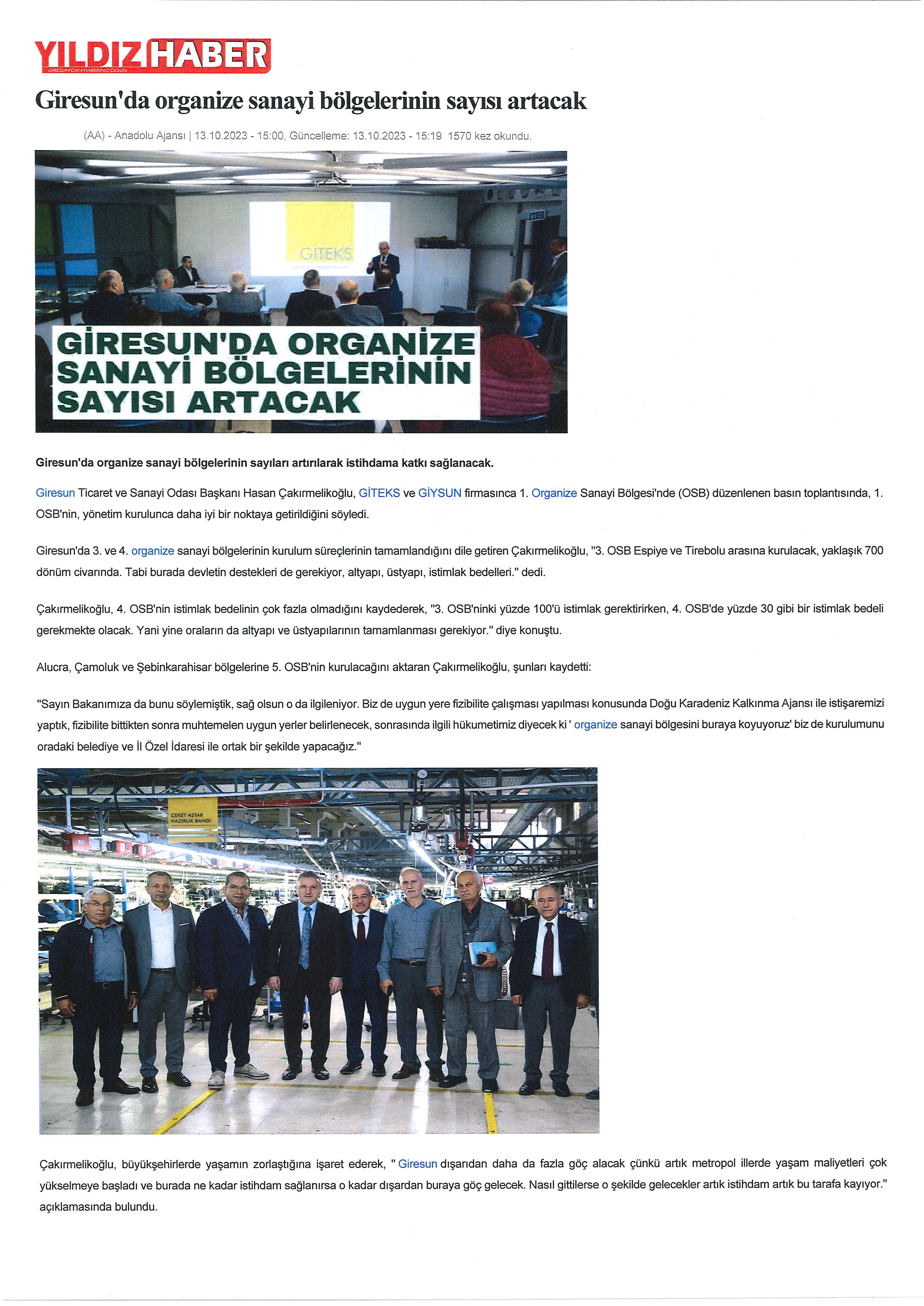

NEWS